File material. Material selection directly affects the final result of a product after the whole production process. Generally, according to the carbon content of the material, the file material is divided into T12 and T10. In addition, wood files also use 45# steel, chain saw files, and needle files use bearing steel and other different materials.

The carbon content of T12 is 1.15-1.24%, and the hardness after heat treatment can reach 58-62hrc; Theoretically, the carbon content of T10 should be 0.95-1.04%. However, due to the current market situation, no domestic manufacturer uses regular T10 steel to make steel files. If there is no industrial chain to make this material in an industry, the cost of using T10 alone may be higher than that of T12. At present, all-steel files claimed to be made of T10 material in China are made of miscellaneous steel. The so-called miscellaneous steel is recycled steel, which may be track steel, spring steel, and pipeline steel. It is not that the steel itself is poor, but in the process of recycling, due to the limitation of the manufacturing process, the final effect of manufacturing is not good. It is possible that there are many impurities and unstable performance. Because it is miscellaneous steel, This process cannot be controlled, but it is also due to this randomness, which can greatly reduce the cost.

At present, if we want stable material, hardness, and product performance in China, we can only suggest T12 material. This industrial chain is complete and synonymous with good quality. Even the effect made by ordinary small manufacturers will not be too bad. If it is a big manufacturer, of course, it will be better, and the quality control will be more strict. The only drawback of this material is expensive. However, if you are a quality-sensitive company, facing the strict requirements of professional customers and want long-term cooperation, we believe that the cost performance of the T12 files is much higher than T10, at least there are not so many unnecessary quality complaints.

- Heat treatment. The heat treatment process itself plays a crucial and decisive role in the hardness of the finished file. Let’s imagine this situation. The file is made of good T12 material, but if the heat treatment process is not done well, it will be a waste of the boss’s real gold and silver.

In the heat treatment process, the file is generally treated by a salt bath furnace. Some foreign factories use high-frequency coil heat treatment. Before, some domestic manufacturers tried to use this seemingly fast and simple method, but as far as I know, there is no domestic factory has completely abandoned the traditional salt bath furnace method.

The so-called salt bath furnace method is to pour salt Sodium Chloride into the crucible, heat it to make it dissolve into liquid, immerse the file completely, take it out after reaching a certain temperature and a certain time, and immerse it in cold water immediately for cooling with a specific method. The alloy steel molecules are rearranged in the whole quenching process, and the performance becomes brittle and hard. After the experience in hot fire and cold water, the T12 steel file hardness can reach 58-62hrc.

In this process, the workers must ensure enough time for the heating in the salt bath, and the file needs to be turned constantly to make uniform heating during the heating process.

The method of putting the file into cold water is also very important. Skilled technicians will choose the appropriate launching angle and speed according to the size and shape of the file, and make appropriate adjustments according to the actual hardness effect.

- File body treatment process.

The treatment process of the file body will also affect the hardness of the finished product after heat treatment.

For example, after tempering, there is an oxide layer on the surface of the billet, which is also called the decarburization layer. This part is not only just the gray oxide layer seen by the naked eye. After a long time of high temperature, the surface of the steel substrate about 0.2mm will also be partially decarburized. That means the carbon content is lost on the basis of about 1.2%, and the degree of loss varies due to heating time, billet shape, size, and stacking, Therefore, this part needs targeted polishing, to ensure that the carbon content is within the standard level.

The sharpness of the file.

As the saying goes, “if you want to be good at something, you must sharpen its tool first”. Using a sharper file can often achieve twice the result with half the effort. Sharpness is a feeling of use. A file with fast cutting, labor-saving, and delicate hand feel is usually regarded as a sharp file.

- File Tooth depth, also called tooth height

- File Tooth pattern angle

- Lean management

How to make a sharp file is the ultimate goal of every file factory that pays attention to customer experience.

The edge of the file is the grain of the file, and the file grain is also the key to determining whether it is sharp or not.

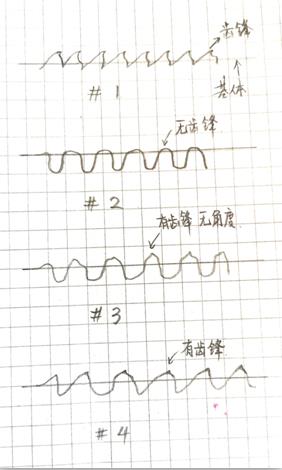

As shown in Figure 1, it is an ideal tooth shape. If you only look at this figure, you may not see the advantages, but once you make a comparison, you will understand that its advantages are still obvious.

As shown in Figure 1, it is an ideal tooth shape. If you only look at this figure, you may not see the advantages, but once you make a comparison, you will understand that its advantages are still obvious.

Figure 2 is an exaggerated practice of tooth pattern, which is equivalent to smashing several grooves with wide spacing on the billet. Because there is no tooth edge, there is no sharpness. In use, it is just slipping and laborious.

The method of drawing No. 3 should be relatively better. The appropriate spacing will make the steel between the lines rise high. If it is matched with the cutting edge angle of the chopper, the rising steel will form a peak. The effect of filing and cutting with this form of the file will be much better in the process of use.

In Figure 4, by adjusting the angle of the chopper, the tooth edge of the file will be biased to one side, which is a bit like a saw-tooth. We call this kind of file tooth edge good, easy to use, and fast cutting. Of course, if we can achieve the reasonable spacing of tooth patterns as shown in Figure 1, the angle of tooth patterns rising is uniform, and the top tip is wide at the bottom, such teeth are sharp and durable.

The key to getting a good cutting edge is to adjust the cutting angle.

The angle of the chopper needs to be determined according to different files and different tooth patterns. For the factory, it is not easy to find such an “expert” skilled technician for grinding and chopping knives in each workshop. The workshop manager needs to make a good system to ensure that all workers operate correctly.

The angle of tooth pattern tests the organization and management ability and lean management ability of a factory.

Have a look at our sponsored chainsaw file test and also our video on manual chain sharpening

text or whatsapp us

text or whatsapp us  orders@chainsawbars.co.uk

orders@chainsawbars.co.uk

sign me up

sign me up basket

basket

![P-3-FILES-48 Panther 4.8mm[3/16"] Chainsaw Files x3 – Files .325 Chains](https://www.chainsawbars.co.uk/content/uploads/Panther-Pack-of-3-Chainsaw-Files.jpg)