To find chains that fit this bar please keep scrolling down the page…

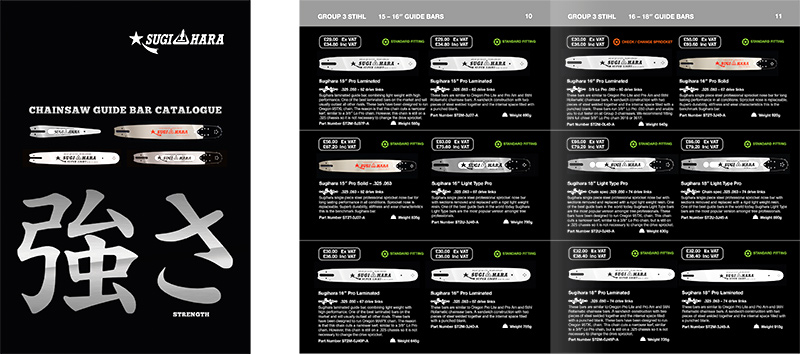

There are 3 types of Sugihara Guidebar – Pro Laminated, Pro Solid and Light Type pro. Have a look at the second picture above in the gallery to see how these bars differ.

What makes a Sugihara bar so good? This is a difficult question to summarise easily.

Sugihara bars started manufacturing chainsaw bars in 1967 by Hideo Sugihara. Japan has always had a reputation for excellence forging and working steel. Having the knowledge to manufacture quality chainsaw bars is not something that is gained overnight. It is a complex process of which cutting out the initial bar is only one part.

Steel has different properties dependant on how it is heated then cooled. Sugihara bars may go through the process of heating and cooling up to 4 times on different parts of the bar in order to gain maximum performance. The rails need to be accurately cut and hardened but over hardening can make them brittle. The bar body needs to be stiff yet flexible. We have used a number of different chainsaw bars over the years including all the major manufactures. Sugihara bars are the hardest wearing bars out there. Even their laminated bars will outlast rivals.

On the single piece pro and light type bars the hardness of the rails is measured at HRC 60. Compare this to Stihl at HRC 57 and Oregon at HRC 55 and it is clear why these bars last longer. They are so hard they resist most flat files when it comes to bar dressing (we recommend a diamond dressing knife which can be found here).

However bear in mind they are more ‘thoroughbred’ in that if they are mistreated and the bar gets over heated they are more prone to chipping. In the wrong hands these bars have a far shorter lifespan so please be aware of your bar maintenance:

-

Check your drive rim/drive sprocket BEFORE you buy a new bar – if worn you MUST change this before running a brand new high tolerance bar

-

Old chains [yes if they have a been used ‘a few’ times this counts as old – must NOT be run on a new bar [or you can but you will likely wear the bar much faster]. If in doubt do not do it.

-

DO bed in your new bar and allow all the different parts to begin the bedding in process

text or whatsapp us

text or whatsapp us  orders@chainsawbars.co.uk

orders@chainsawbars.co.uk

sign me up

sign me up basket

basket

![[MULTI1] BN6A-0X40T-A Sugihara Tough Carver Dime Tip 16"[40cm] 1/4 .050 84 drive links](https://www.chainsawbars.co.uk/content/uploads/16-1.gif)

![[U1-16] BN6A-0X40T-A Sugihara Tough Carver Dime Tip 16"[40cm] 1/4 .050[1.3mm] 84 drive links - Image 5](https://www.chainsawbars.co.uk/content/uploads/Sugi-A4-flyer-25.07.2018-40-2.jpg)

![[U1-16] BN6A-0X40T-A Sugihara Tough Carver Dime Tip 16"[40cm] 1/4 .050[1.3mm] 84 drive links - Image 6](https://www.chainsawbars.co.uk/content/uploads/Sugihara-Catalogue-AGL-04-40-2.jpg)

![[MULTI1] BN6A-0X40T-A Sugihara Tough Carver Dime Tip 16"[40cm] 1/4 .050 84 drive links](https://www.chainsawbars.co.uk/content/uploads/Sugi-A4-Stihl-5-10.jpg)

![[MULTI1] BN6A-0X40T-A Sugihara Tough Carver Dime Tip 16"[40cm] 1/4 .050 84 drive links](https://www.chainsawbars.co.uk/content/uploads/CB-A4-AD2-14.jpg)

![[MULTI1] BN6A-0X40T-A Sugihara Tough Carver Dime Tip 16"[40cm] 1/4 .050 84 drive links](https://www.chainsawbars.co.uk/content/uploads/16-1-100x100.gif)

![[U1-16] BN6A-0X40T-A Sugihara Tough Carver Dime Tip 16"[40cm] 1/4 .050[1.3mm] 84 drive links - Image 5](https://www.chainsawbars.co.uk/content/uploads/Sugi-A4-flyer-25.07.2018-40-2-100x100.jpg)

![[U1-16] BN6A-0X40T-A Sugihara Tough Carver Dime Tip 16"[40cm] 1/4 .050[1.3mm] 84 drive links - Image 6](https://www.chainsawbars.co.uk/content/uploads/Sugihara-Catalogue-AGL-04-40-2-100x100.jpg)

![[MULTI1] BN6A-0X40T-A Sugihara Tough Carver Dime Tip 16"[40cm] 1/4 .050 84 drive links](https://www.chainsawbars.co.uk/content/uploads/Sugi-A4-Stihl-5-10-100x100.jpg)

![[MULTI1] BN6A-0X40T-A Sugihara Tough Carver Dime Tip 16"[40cm] 1/4 .050 84 drive links](https://www.chainsawbars.co.uk/content/uploads/CB-A4-AD2-14-100x100.jpg)